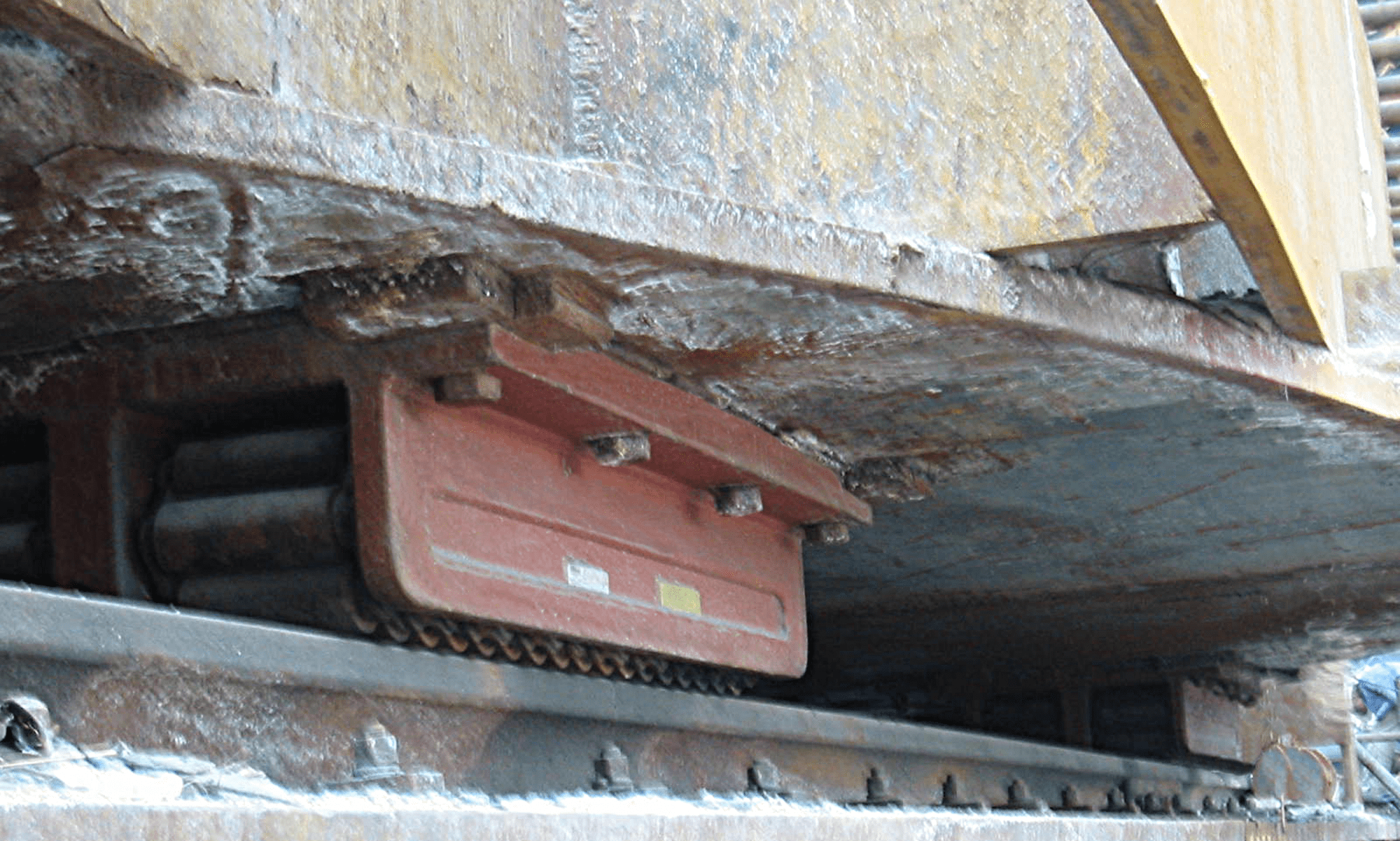

The company Boerkey is the inventor of the Roller Skate Express. By the help of this mechanical product, loads of several tons can be moved easily and safely.

The basic principle of the Roller Skate is based on a simple but ingenious idea: Already during the construction of the pyramids in Egypt, heavy components were moved by rollers, but the released rear roller always had to be brought manually forward under the load.

In the case of the Roller Skate, this happens automatically, as the rollers are joined by links to form a roller chain. This significantly reduces the risk of accidents and allows an easily and continuous transport.

Since 1951, the Roller Skate has been manufactured in Hagen in Germany and is successfully used by our customers worldwide.

As a supplement to our product range, we have been producing very robust heavy duty rollers and heavy duty trolleys for many decades.

In the following, we would like to show you a small excerpt from our projects for moving heavy loads ….