The Idea

In the beginning there was the idea: The idea to move heavy loads with rollers and to bring the released roller automatically to the front and under the load again. This significantly reduces the risk of accidents and allows easier and continous transport.

These considerations resulted in the material handling equipment for heavy and heaviest loads- THE INDUSTRIAL ROLLER SKATE

The Advantages

- solid construction guarantees low maintenance and long lifetimes

- low height (standard minimum at 63mm, special constructions minimum at 53mm) reduces the risk of tipping, can be used as a mini-crane wheel or as a chassis and requires only a small load lift or load remaining at a low height

- low friction (for large roller diameters under ideal conditions less than 3% of the total load)

- total absence of a higher starting friction (big advantage versus any glide pad solution)

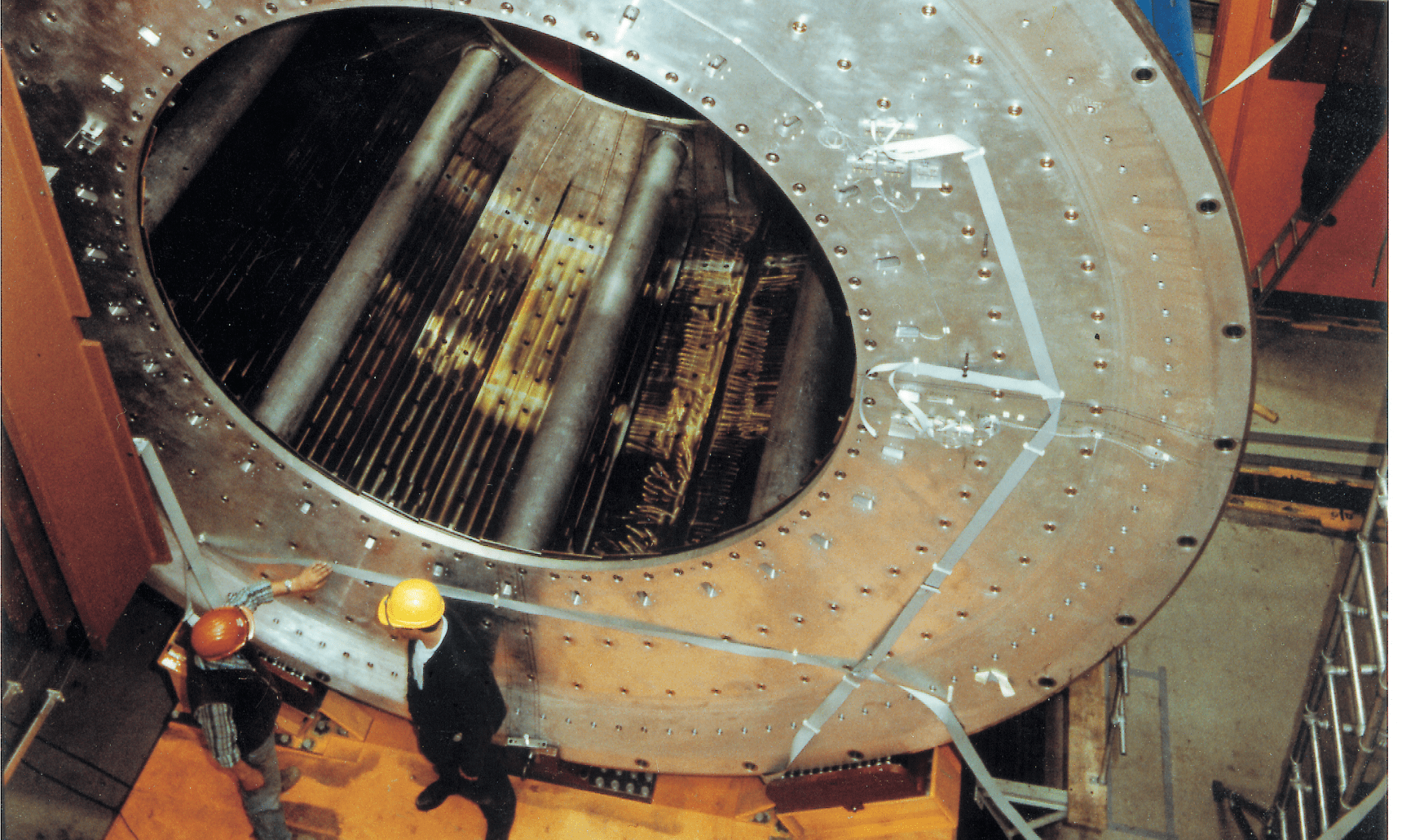

- decades of experience (over 60 years) in the use of Rollerskate Express offshore (on, under and in the water) and onshore (bridge construction and displacement, transportation of complete houses and sports grandstands, of large plants (blast furnaces), large machinery, hangar doors, reactor parts, as machine part in tube bending machines

- universal transport device or heavy roller conveyor

- very cost-effective component

Model N

Range of application

- For short variable movements

- Movement of moderately heavy loads, e.g. machines, parts of machines, steel and concrete components on construction sites

- Allows turning by using optional turntables, packing plates and handles

- Frequently used as complete transport kit

- Easy alignment with optional link-up bars

Range of application

- For short variable movements

- Movement of moderately heavy loads, e.g. machines, machine parts, steel and concrete components on construction sites

- Allows turning

Transport sets

Model C

Range of application

- For short distances

- Movement of moderately heavy loads, e.g. in ovens, technical equipment, for concrete formwork, in stocking techniques

- can be welded to the load

- lowest height

Range of application

- For short distances

- Movement of moderately heavy loads, e.g. scaffolding and concrete framework on construction sites

- Can be bolted to the load at the lowest possible height

Model B

Model A

Range of Application

- For short distances

- Movement of heavy loads in mining, steel, machine and bridge construction or as heavy roller conveyors (rollers facing upside-down)

- Very stable construction due to the top plate

- Can be bolted to the load

Range of application

- For longer distances and/or permanent loads due to lateral (S) chain guide

- Movement of heaviest loads for extended periods of time and distances e.g. progressive shifting of scaffolding and formwork in bridge construction, bridge displacements, gantry cranes , hangar doors of PAS, BOP cranes on drill rigs, polar cranes in nuclear power stations

- Very stable construction due to top plate

- Low wear due to chain guide / long lifetime (no contact between chain and side parts, thus no wear of the bolt heads of the chain)

- Can be bolted to the load

Model AS-H

Model AM-H

Range of application

- For longest distances, permanent loads and permanent movements due to middle (M) chain guide

- Movement of heavy loads for longest periods of time and distances (e.g. bridge scaffolds, telescopic cantilever beams, gantry cranes, lock gates or as machine components)

- Very stable construction due to top plate

- Low wear due to chain guide / longest possible lifetime (no contact between chain and side parts, thus no wear of the bolt heads of the chain)

- Can be used inclined by 90° as heavy load side guide with optional Double M-guide

- Can be bolted to the load

Applications

- twin combination (Z) of models AS-H or AM-H

- for longer travel distances under continous load with particularly high point loads and with particularly small installation dimensions

- often used in bridge constructions as well as mobile equipment for supporting hydraulic cylinders

- also available as a triple or quadruple combination on request

Model Z

Guide Rollers

Applications

- for longer travel distances and/or continous loads with aditional lateral load

- useable on suitable lanes such as (crane-)rails and/or girders

- the number and arrangement of the guide rollers is individual and determined by the customer

If you can not find a suitable roller skate in our extensive standard program, we will gladly create an individual construction that perfectly matches your project.

More than 2,700 special constructions created so far for our customers bear witness to our decades of experience in moving heavy loads