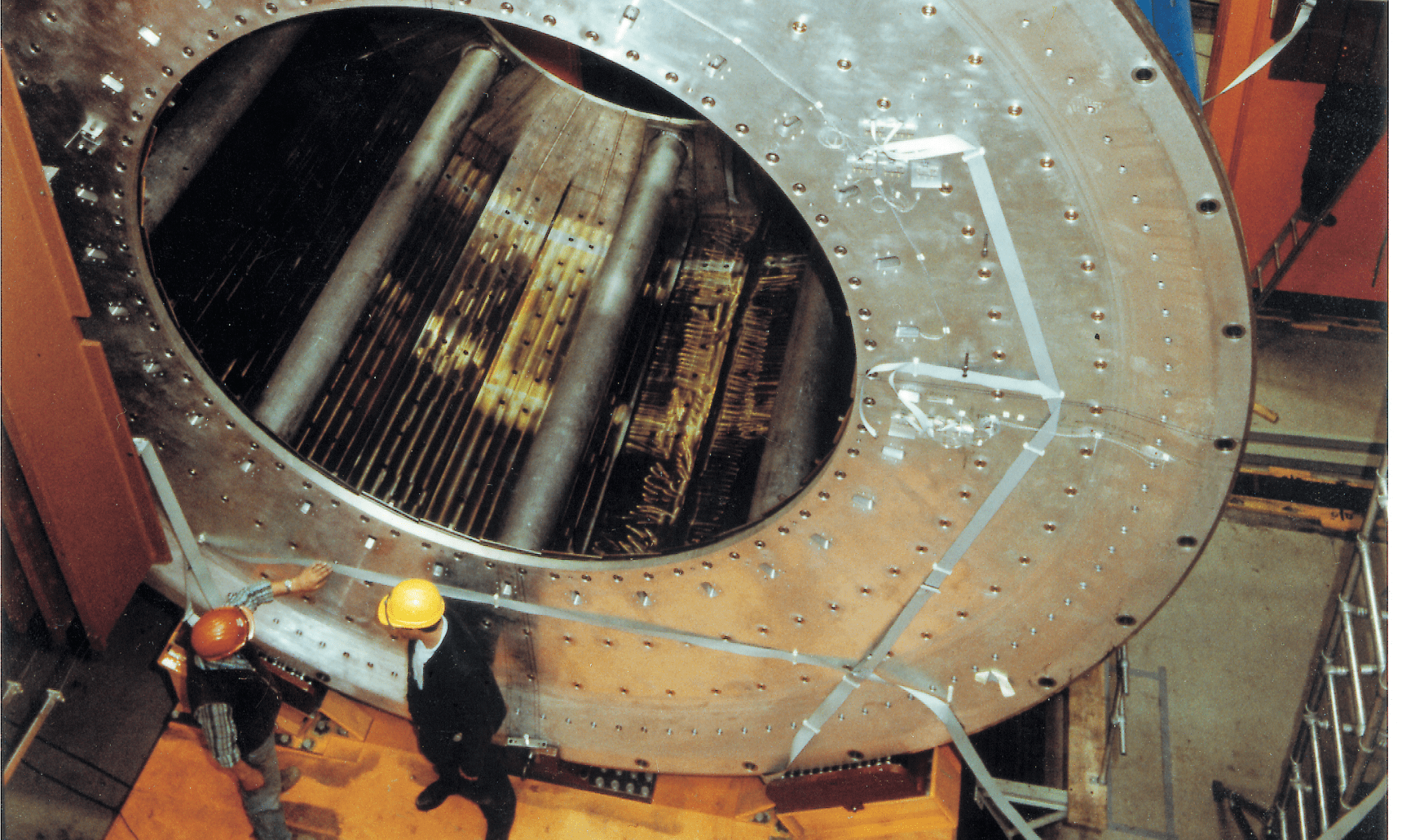

Applications

- For short distances

- Movement of moderately heavy loads e.g. to transport materials in ovens, for shuttering, concreting or stocking techniques

- can be welded to the load

- ideal model for confined spaces

Key features

- Stable, solid basic construction

- Low level construction and smooth top achieved after welding, models N and B are the same height

- can be welded to the load to ensure Roller Skates and load are firmly connected

- Available with hardened center plate (=models C-H) or additional with higher tensile rller material 50CrV4 (=models C-H-50CrV4)

Hints on use:

- If the rollers are being used to their maximum carrying capacity or with lengthy intervals between use, choose models with a hardened center plate (=model C-H)

- In case of possible overload, choose chain roller material 50CrV4

- maximum speed: 5m/min

- The rolling resistance depends on the track. For smaller models I-IIIv 7-5%, for larger models 5-3% of the total load

- Can be arranged with guide rollers

- For scaffolding application the chain alone can be used (length according to customers’ specification)

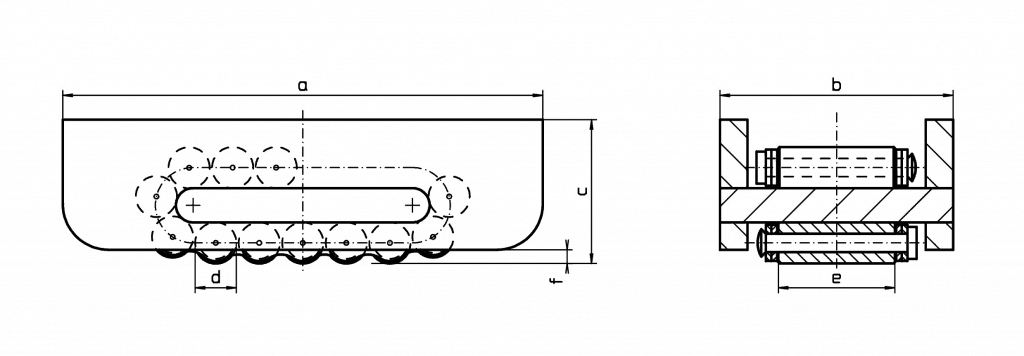

Mod C, C-H (H= hardened and machined center plate)

C-H-50CrV4 (roller material 50CrV4)

| Size | a | b | c | Ød | e | f | Supporting rolls | Roll number | Capacity max kN | Weight kg |

|---|---|---|---|---|---|---|---|---|---|---|

| I | 210 | 100 | 63 | 18 | 51 | 6 | 5 | 15 | 100 | 5,0 |

| II | 220 | 113 | 73 | 24 | 60 | 10 | 4 | 13 | 150 | 7,0 |

| III | 270 | 130 | 90 | 30 | 68 | 10 | 4 | 13 | 300 | 12,5 |

| IV | 380 | 168 | 126 | 42 | 76 | 19 | 4 | 13 | 600 | 32,0 |

| V | 530 | 182 | 146 | 50 | 86 | 19 | 6 | 17 | 800 | 61,0 |