Range of Application

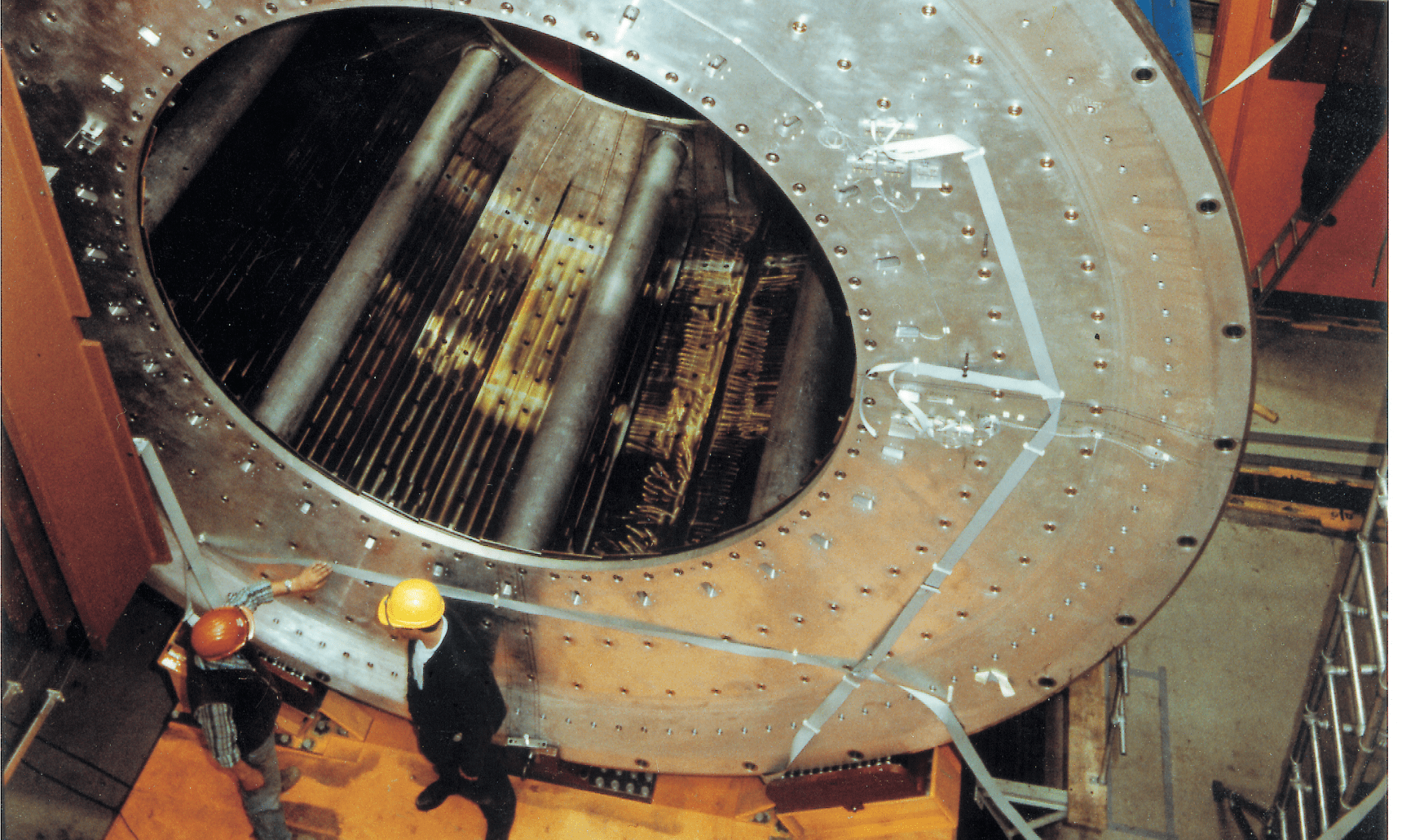

- For longer distances and/or continuous movement with continuous load through medium (M) chain guide

- Movement of heavy loads for longer distances or for a long time e.g. for movements as a machine component, heavy duty telescope, guidance, in the machine engineering industry.

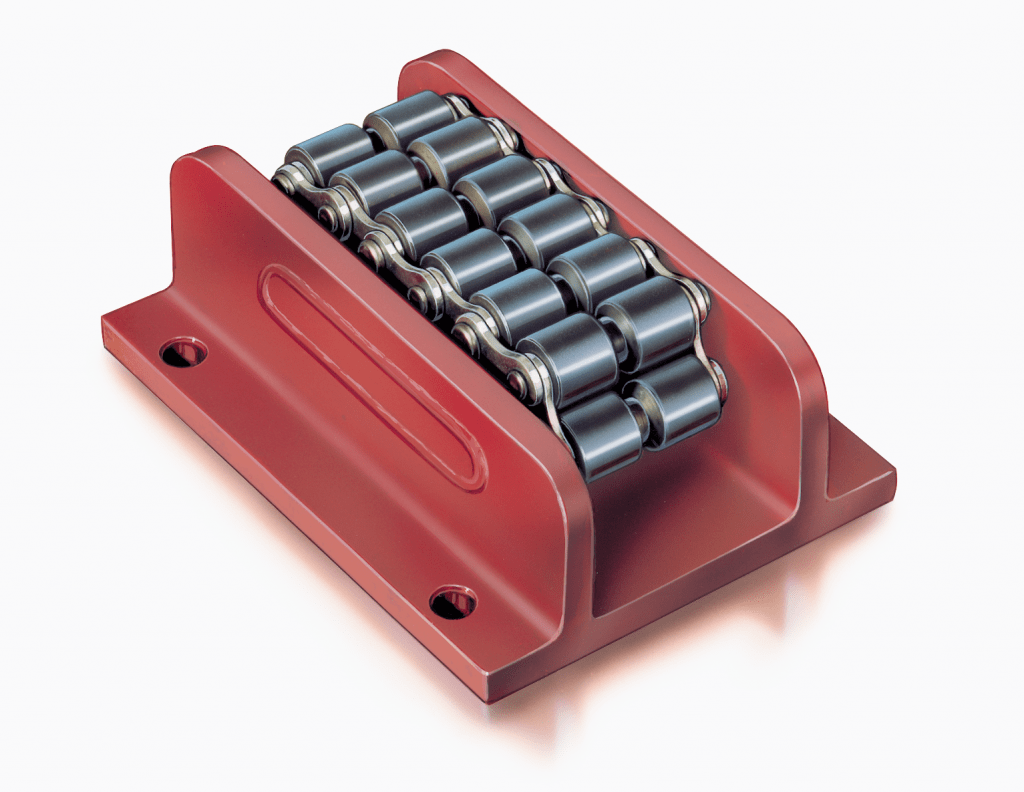

- particulary stable construction through continious cover plate

- particulary wear-resistant due to chain guide (no lateral starting of the hain, mthus no wear of the bolt heads)

- can be bolted to the load

Key Features

- Extra robust construction

- Low level construction with higher carrying capacity, exchangeable with models …AS and …A due to same outer dimensions

- More stability achieved, if load is firmly bolted to roller skates

- More stable operation and distribution of load

- Reduced wear by center plate chain guide (no contact between chain and sidewalls, no wear to rivet heads)

Hints on use

- Check with the manufacturer before selection of skates for use in a vertical posistion

- Models I-IIIv have 4 bolt holes as standard

- If problems of load distribution occur e.g. by wind forces, it is necessary to select moedel AM-H_50CrV4

- Maximum speed: 5m/min

- The rolling resistance depends on the track. For smaller models I-IIIv 7-5%, for larger models 5-3% of the total load

- Available with http://boerkey-gmbh.de/de/produktuebersicht/fuehrungsrollen/

- Location of the fixing holes can be arranged to suit customers’ requirements

- Optional in galvanised or stainless steel construction

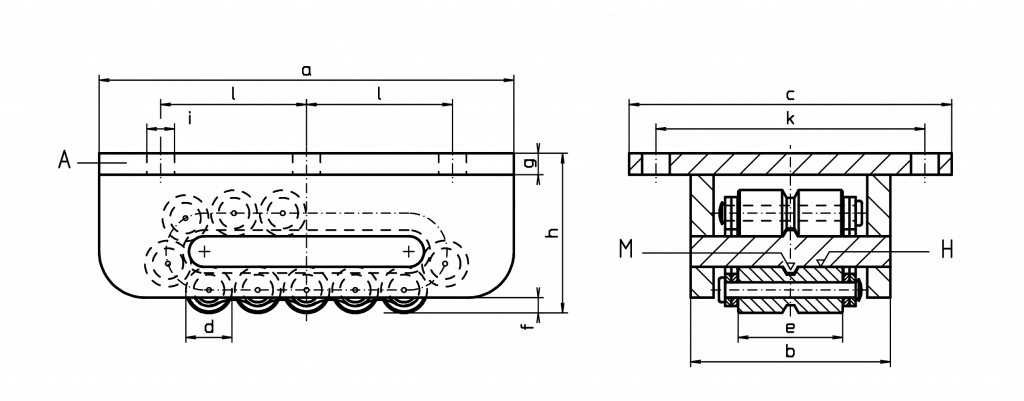

Mod. AM-H

(H=hardened and machined center plate)

AM-H-50CrV4

(roller material 50CrV4)

| Size | a | b | c | Ød | e | f | g | h | Øi | k | l | Supporting rolls | Roll number | Capacity max kN | Weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 210 | 100 | 175 | 18 | 51 | 6 | 13 | 76 | 14 | 140 | 75 | 5 | 15 | 125 | 8,8 |

| II | 220 | 113 | 190 | 24 | 60 | 10 | 14 | 87 | 14 | 155 | 75 | 4 | 13 | 170 | 11,5 |

| III | 270 | 130 | 210 | 30 | 68 | 10 | 14 | 104 | 18 | 175 | 95 | 4 | 13 | 330 | 19,0 |

| IIIV | 320 | 140 | 220 | 30 | 68 | 10 | 18 | 115 | 18 | 180 | 120 | 6 | 17 | 420 | 28,5 |

| IV | 380 | 168 | 270 | 42 | 76 | 19 | 19 | 145 | 22 | 220 | 140 | 4 | 13 | 530 | 50,0 |

| V | 530 | 182 | 300 | 50 | 86 | 19 | 19 | 165 | 22 | 240 | 205 | 6 | 17 | 690 | 89,5 |

| VL | 580 | 182 | 300 | 50 | 86 | 19 | 23 | 170 | 26 | 250 | 250 | 8 | 21 | 880 | 104,0 |

| Vv | 650 | 205 | 350 | 50 | 100 | 20 | 28 | 190 | 26 | 280 | 240 | 9 | 23 | 1250 | 156,0 |

| VI | 900 | 205 | 380 | 50 | 100 | 20 | 38 | 200 | 33 | 300 | 360 | 13 | 31 | 1650 | 237,0 |